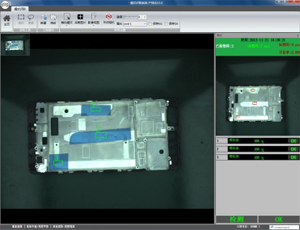

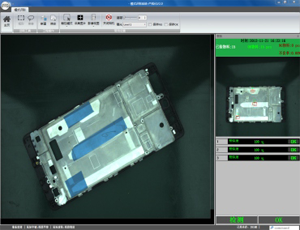

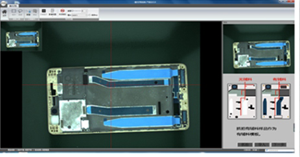

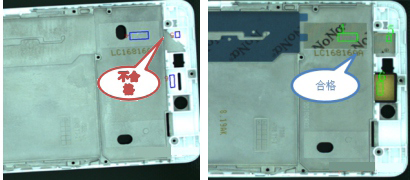

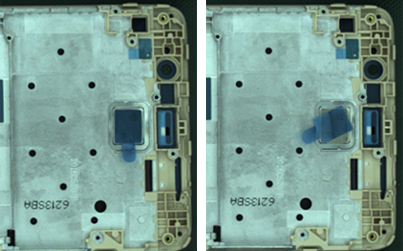

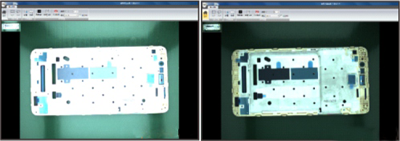

The system can recognize a shape of a measured sample, recognize complicated sample patterns, various location arrangements of the sample, and deformation of the sample, and also inspect a large amount and various types of measurement samples at the same time by applying the ultra depth technology. Under the inspection condition, the accuracy of identification amounts to more than 99.9%, a processing speed is high, a location arrangement is accurate, and data analysis can be performed in real time. The technology can be applied to inspection and identification of various dimension or pattern matching. Even if a contrast in an image of a sample is low, very high accuracy of identification can be maintained.

-

High speed80mm/s

-

High resolutionOptical lens with 5 million pixels

-

High accuracy99.9% or higher

-

Wide field of view180mm x 140mm