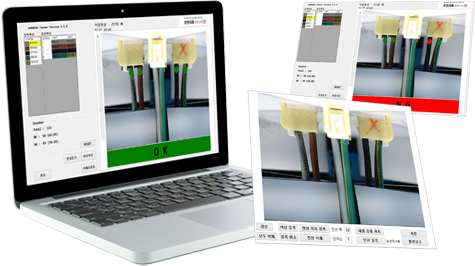

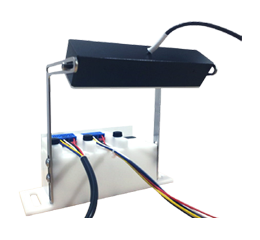

1-row wiring inspection

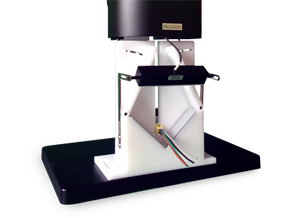

Variable jig

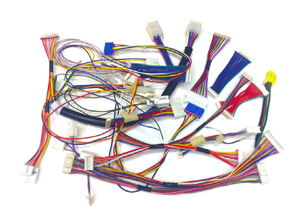

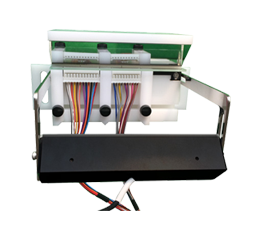

1-row wiring and 2 connectors

Variable jig for simultaneous inspection

1-row wiring and terminal inspection

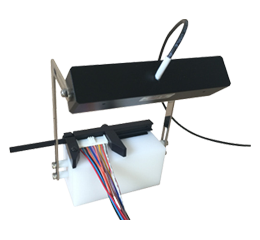

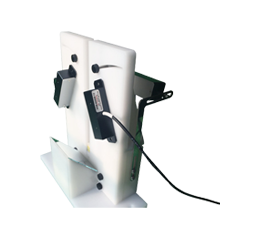

rear-side prism-type variable jig

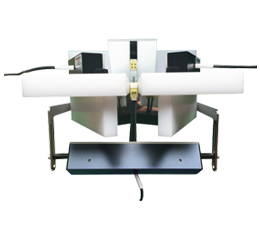

2-row wiring inspection

V-block jig

2-row wiring and terminal inspection

rear-side prism-type V-block jig

'TOS'는 (이하 '회사'는)고객님의 개인정보를 중요시 하며, "정보통신망 이용촉진 및 정보보호"에 관한 법률을 준수하고 있습니다. 회사는 Privacy policy을 통하여 고객님께서 제공하시는 개인정보가 어떠한 용도와 방식으로 이용되고 있으며, 개인정보보호를 위해 어떠한 조치가 취해지고 있는지 알려드립니다. 회사는 Privacy policy을 개정하는 경우 웹사이트 Notice(또는 개별공지)을 통하여 공지할 것입니다. * 본 방침은 2016년 07월 01일부터 시행됩니다.

회사는 상담, 견적의뢰 등을 위해 아래와 같은 개인정보를 수집하고 있습니다.

- 수집항목 : 이름, Name, 직책, 비밀번호, 전화번호, Address, 휴대전화번호, 이메일

- 개인정보 수집방법 : 홈페이지 문의(A/S신청)

회사는 수집한 개인정를 다음의 목적을 위해 활용합니다.

- 서비스 제공에 관한 계약이행 및 서비스 제공에 따른 요금정산

- 회원관리 : 홈페이지 제작에 따른 본인확인, 개인식별, 불만처리 등 민원처리, 고지사항 전달, 이벤트

회사는 개인정보 수집 및 이용목적이 달성된 후에는 예외 없이 해당 정보를 지체 없이 파기합니다.